Wayfarer Build

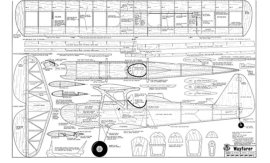

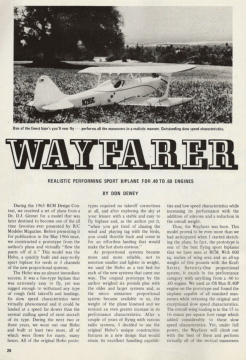

Why build the Wayfarer? First, the odds of someone else having this aircraft at the local field is just about zero. Second, No wires to bend for the upper wing cabanes. And third, I like biplanes. Designed by Don Dewey, the articles I read about how this bird flies were impressive. Fast or slow, with no bad habits, it seems to do it all well—I just had to build one. Derived from an earlier airplane called the Hobo, the Wayfarer is a well tested platform. The airplane was also kitted by Tenco- International and Svenson in years past. Svenson also kitted a smaller version of the Wayfarer called the Twinny. Wayfarer assembly is straightforward with few parts to cut out.

Wing Assembly

Bottom wing dihedral braces being glued to spars while setting dihedral. Wing construction is egg crate style. Notches in the ribs, and notches in the spars make the egg crate. It was my first time with this type of wing construction. It worked OK. Using a jig would have made it easier. .Top View

Fuselage was rubber banded together to check for fit and alignment. Top stringer and F5 to be added to center section of aft fuselage. 1/4 inch spruce stringer will be fitted to top of formers to support turtledeck sheeting.Another Top View

Fuel tank is basically a permanent installation. Setting up the tank and installation is easily done before forward fuselage sheeting is completed.

Aft Fuselage Sheeting

Installed

Headrest was cut from glued balsa

blocks and sanded to shape.

Top Wing Mounts

Horizontal supports will be permanently

glued and painted after covering. It will

make covering much easier. Reliefs in

top sheeting were filled with mixture of

Zap Z-Poxy Finishing Resin and micro

balloons.

Tail Section

Tail pieces pinned in place. Fairing

blocks will need to be shaped.

Gussets were added to horizontal

stab. It flexed a bit more than I liked

after assembly.

R/C Aircraft Insight From Low Altitude

Business End Of The Wayfarer

Power up front will be handled by a

Saito 56. It should fly the aircraft

quite well Not looking for unlimited

vertical here, just an easy relaxed

flier. I want to take advantage of its

slow speed qualities.

Front Sheeting Added

3/32 sheeting was dampened, bent

to shape and glued over front

fuselage formers. Landing gear was

cut from aluminum and bent to

shape.

Wayfarer Pilot

Yep, the Wayfarer pilot happens to

be a big fan of Spam. Cap was made

with paper mache. Flour, water, and

newspaper. Thin cardboard for brim,

cut to shape, then glued to cap.

Fly Safe!

John W. Blossick

Tail Slide Haven

johnb@tslidehaven.com

May 2018

Cockpit Detail

I put together a quick cockpit dash

using a JTEC instrument kit and

stained the plywood.

Covered!

Ultracote was used for covering.

Turquoise and a medium blue were

chosen for the covering scheme.

Find The Best Deals In R/C

More Build Notes and Maiden Flight

There’s hardly a completed build where I wish I had done a few things differently. The

Wayfarer was no exception. If I were to build another one, I’ll add a removable top

tank hatch as shown on the Svenson plan. If using a 4 stroke engine again, I will set

the firewall back about 1 1/4 inches to compensate for the weight and length of a 4

stroke engine vs. a .40 two stroke engine. I had to add weight to the tail to balance

the airplane, which is unusual for a tail dragging biplane.

Also, I lowered the Saito .56 about 1/2 inch from the plan thrust line to make it sit

better in the airplane. The thrust line is fine for a two stroke engine but the 4 stroke

sat too high (at least to me), on the engine mounts and just looked stupid. In flight the

airplane doesn’t seem to care. No major elevator trim is necessary for level flight.

Next, I would probably trash the aileron bell cranks and go with dual servos for the

ailerons.

And finally, if you build a Wayfarer, use solid med hard, to hard balsa on the

horizontal stabilizer. Do not use the open framework as shown on the plan.

I’ve read of horizontal stabilizer failure on this airplane and figured I would add a few

gussets to the framework to be safe. It didn’t really help.

On the maiden flight the Wayfarer tracked nice and straight with a touch of right

rudder and was off in about 30 feet. I was climbing out, left hand turn, level off to

check the trim, and started another left turn to bring the ship around. That’s when the

problems started.

After gently banking to the left and easing in the up elevator to turn, the airplane

would roll in the opposite direction. I was able to level the plane off and bring it over

the runway. I made another circle around the field but it seemed to be getting worse.

Every time I moved the elevator the airplane would roll. Time to land!

Using throttle to control descent, I came in a little hot, landing in the grass and ended

up just breaking the propeller. Upon checking the airplane after landing, the horizontal

stabilizer would flex when the elevator was moved up or down. The Horizontal

stabilizer would also flex just by holding it and giving it a little wiggle. Not good.

Instead of cutting the airplane apart and replacing the stabilizer, I decided to remove the bottom covering and fill in all the open areas of the stabilizer with 1/4 inch balsa. After sanding it all flush, I fiberglassed the bottom of the stabilizer with 3/4 oz cloth and recovered it. Now there is no flex whatsoever in the stabilizer. Any weigh gain was negligible, only 3/4 ounce of tail weight was still needed to balance the 5 pound airplane.On most models, stab/elevator area is about 17-18% of the total wing area. Although I

haven’t done the calculations, the Wayfarer horizontal stabilizer and elevator just

looks unusually large—perhaps 20% of the wing area or more. It should be stressed

accordingly.

In any event, I highly recommend deviating from the plans on this one by using solid

wood for the horizontal stabilizer.

Wayfarer Biplane

tslidehaven.com

Top of Page